2023-10-20

Source:Jiahe Precision Forging casting Co., LTD

Category:Industry information

Precision forging forming technology (net forming) refers to the forming technology that only needs a small amount of processing or no longer processing to meet the requirements of parts after forging forming. Precision forging forming technology is an important part of advanced manufacturing technology, and it is also a widely used parts manufacturing process in automobile, mining, energy, construction, aviation, aerospace, weapons and other industries. Precision forging technology not only saves materials, energy, reduces processing processes and equipment, but also significantly improves productivity and product quality, reduces production costs, and thus improves the market competitiveness of products.

After more than 30 years of development, precision forging forming technology has been rapidly developed, and many research results have been achieved. In this paper, the development of precision forging forming technology in recent years is summarized from five aspects, such as process method, equipment, mold, forming process simulation and process optimization, and the future development direction of precision forging forming technology is prospected.

1. Precision forging process

At present, many precision forging processes have been applied to production. According to different forming temperature, it can be divided into hot precision forging, cold precision forging, warm precision forging, compound precision forging, isothermal precision forging and so on.

1.1 Hot precision forging process

The precision forging process where the forging temperature is above the recrystallization temperature is called hot precision forging. Hot precision forging materials have low deformation resistance and good plasticity, and are easy to form more complex workpieces, but due to strong oxidation, the surface quality and dimensional accuracy of the workpieces are low. The common process of hot precision forging is closed die forging. Due to inaccurate blanking, lack of mold design and manufacturing accuracy, the deformation resistance of closed die forging in the final closing stage is great, which causes great damage to equipment and mold.

The common method to solve this problem is the shunt depressurization principle, that is, a shunt depressurization cavity with reasonable shape and size is set at the last place filled by the closed cavity. When the cavity is completely filled, the excess metal of the billet is extruded from the shunt cavity hole, which not only solves the contradiction that the volume of the billet and the volume of the cavity cannot be strictly equal, but also reduces the internal pressure of the cavity, which is conducive to improving the life of the mold.

As early as the 1950s, due to the lack of sufficient gear processing machine tools, the Germans began to use the method of closed hot die forging to test the production of straight bevel gear. The development and application of hot precision forging gear technology in China started in the early 1970s and matured in the middle and late 1980s.

1.2 Cold precision forging process

Cold precision forging is a precision forging process carried out at room temperature. The cold precision forging process has the following characteristics: the shape and size of the workpiece are easy to control, avoiding the error caused by high temperature; High workpiece strength and precision, good surface quality. In the process of cold forging, the workpiece has poor plasticity, large deformation resistance, high requirements for molds and equipment, and it is difficult to form parts with complex structure. In order to overcome the problems of large deformation resistance and poor filling effect of cold precision forging, some new process methods have been developed successively, including block forging, floating die forging, prefabricated split forging and so on.

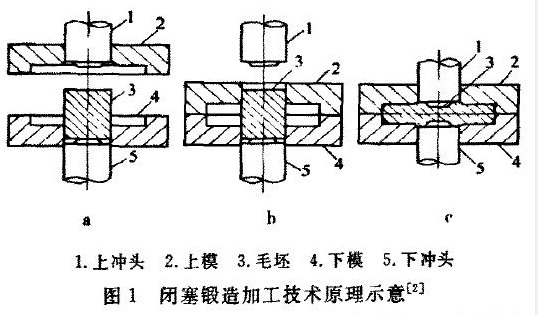

Block forging is a single or opposite extrusion of metal in a closed die by one or two punches. The upper and lower dies used in the block forging processing technology are assemblies, which are respectively composed of the upper die, the upper punch, the lower die and the lower punch. In the forging process, the upper and lower die are first closed to form a closed die cavity, and enough pressure is applied to it, and then the blank in the die is extruded by the upper and lower punch (as shown in Figure 1). In the forging process, the blank is in a strong three-way compressive stress state, good plasticity, can form complex shape parts at one time, high production efficiency, and the metal flow line along the shape of the forging continuous distribution, good mechanical properties of the forging.

The die in floating die forging is not fixed and will float with the forging process. This design reduces the relative speed between the die and the metal deformable, reduces the influence of friction on the contact surface, improves the filling performance of the forging and decreases the deformation resistance.

By setting the overflow port at a certain position of the forging, the material always has free flow room in the process of filling the cavity, so as to improve the filling property of the cavity and reduce the deformation resistance and processing load. In order to improve the shape filling of straight gear precision forging, Zhang Qingping et al. put forward a process method of prefabricated split hole and split forging. In the preforging process, the upper die and the lower die are equipped with a convex table, and a shunt zone is forged in the central part of both ends of the billet. In the final forging, the center diverting area plays the role of diverting the material, improving the flow state of the material, thus reducing the forming load and improving the billet filling property.

In recent years, the cold forging process in China to obtain a certain development, Tike intelligent Equipment Co., Ltd. introduced advanced forging machine and mold processing equipment, is China's current cold forging equipment conditions in the forefront of the enterprise. The annual output of all kinds of precision cold and warm forgings for automobiles and motorcycles reaches 4000t. Some typical high difficulty cold forging parts such as car constant speed universal joint jacket, star sleeve, transmission shaft, etc., have achieved mass production in the factory.

1.3 Warm precision forging process

Warm precision forging is a precision forging process performed at a suitable temperature below the recrystallization temperature. Hot forging precision forming technology not only breaks through the limitations of large deformation resistance in cold forging forming, the shape of the part can not be too complicated, the need to increase the intermediate heat treatment and surface treatment steps, but also overcomes the problem of reducing the surface quality and dimensional accuracy due to strong oxidation in hot forging. It has the advantages of both cold forging and hot forging, and overcomes the disadvantages of both. However, the forging temperature of the warm precision forging process is low, the forging temperature range is narrow, and the forging range is more strict, which requires high-precision special equipment, and has higher requirements for the mold structure and mold materials.

1.4 Composite precision forging process

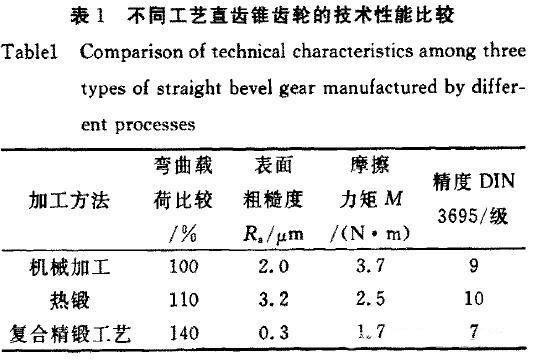

With the increasing complexity of precision forging parts and the improvement of precision requirements, simple cold, warm and hot forging processes can not meet the requirements. The composite precision forging process combines cold, warm and hot forging processes to complete a workpiece forging, which can give full play to the advantages of cold, warm and hot forging and discard the disadvantages of cold, warm and hot forging. Table 1 is a comparison of the technical properties of straight bevel gears produced by three different processes. It can be seen from the table that the mechanical properties, dimensional accuracy and surface roughness of the workpiece produced by composite precision forging are improved compared with the other two processes []. Therefore, the composite forging process is an important direction of the development of the forging process.

1.5 Isothermal precision forging process

Isothermal precision forging means that the blank is formed by die forging at a temperature that tends to be constant. In order to ensure the conditions of thermostatic forming, the mold must also be heated to the same temperature as the blank. Isothermal die forging is often used for the precision forming of titanium alloy, aluminum alloy, magnesium alloy and other hard-to-deform materials in the aerospace industry, and in recent years, it is also used for the precision forming of non-ferrous metals in the automotive and machinery industries.

Isothermal forging is mainly used in forging metal materials with narrow temperatures, especially titanium alloys that are very sensitive to deformation temperature. Isothermal forging parts generally have thin web, high rib and thin wall, such parts blank heat is quickly absorbed by the mold, the temperature drops rapidly, the use of ordinary forging method, not only need to greatly improve the tonnage of the equipment, but also easy to cause the crack of the mold.

1.6 Development trend of precision forging process

With the development of manufacturing industry, the demand for precision forging parts is getting higher and higher, and the research and development of precision forging process is also put forward higher requirements. The main directions of precision forging process research are as follows.

1) Continuous process innovation. In order to meet the requirements of forming parts and reduce the production cost, it is necessary to constantly develop a new precision forging forming process with high forming precision, long die life and high production efficiency.

2) Development of composite technology. With the continuous improvement of the process requirements of forming parts, a single precision forging is difficult to meet the requirements, which requires the development of composite forming process, the forging process of different temperatures or different process methods is combined, learn from each other to complete the processing and manufacturing of a part. The precision forging process can also be combined with other precision forming processes such as precision casting, precision welding, etc., to improve the application range and processing capacity of the precision forming process.

3) Knowledge-based process design. With the continuous development of precision forging process, the process design is becoming more and more complicated. In order to improve the reliability and efficiency of process design, the development of knowledge-based expert system is an important research direction of future precision forging process design.

Online

Online WeChat

WeChat

Tel

Tel

Phone Number:17775124928

Top

Top

Jinggong Industrial Park, Tangcun Town, Jiahe County, Chenzhou City, Hunan Province, China

Home

About

Company profile Qualification PartnerProducts

Casting part SAE flange Forging partsWorkshop

Factory appearance Casting shop Forging shopCustomized

Process introduction Cooperation process Cooperation advantageCase

News

Company news Industry information FaqContact

CNC machining